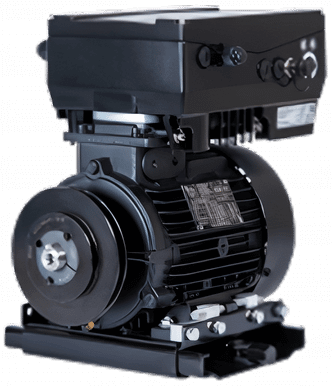

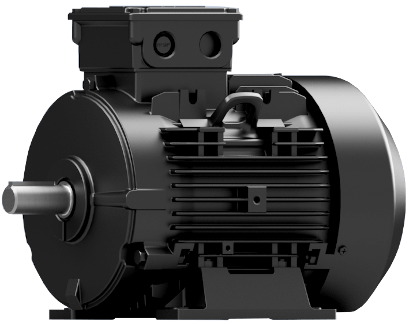

The synchronous high performance standard motors of the ZPM series are brushless permanent synchronous motors with counter-EMF. They have buried permanent magnets in the rotor. The stator contains a three-phase winding that can be connected in a star or delta configuration and is supplied by a frequency converter.

The motor has no brushes, the commutation is done electronically in the corresponding frequency converter.

Available from stock.

Request offer

Data sheets